One of the hallmarks of the companies that we feature on our Making It In NYC tour series at the Brooklyn Navy Yard is that they wed traditional crafts with advanced technology to create unique, innovative, and competitive products. Scott Jordan Furniture is a perfect example of this union.

Founded in 1980, the company has had its home at the Brooklyn Navy Yard since 1988, back when there were fewer neighbors and fewer amenities than you find around the Yard today. Since the company’s inception, the eponymous Scott Jordan and his team have made solid wood beds, tables, chairs and other home furnishings by hand with original designs.

But after nearly 20 years in business, the company went through a radical transformation when in 1999, they purchased a Computer Numerical Controlled Router, also known as a CNC machine. This has changed not only their manufacturing process, but basically every aspect of the business, from design to purchasing to sales.

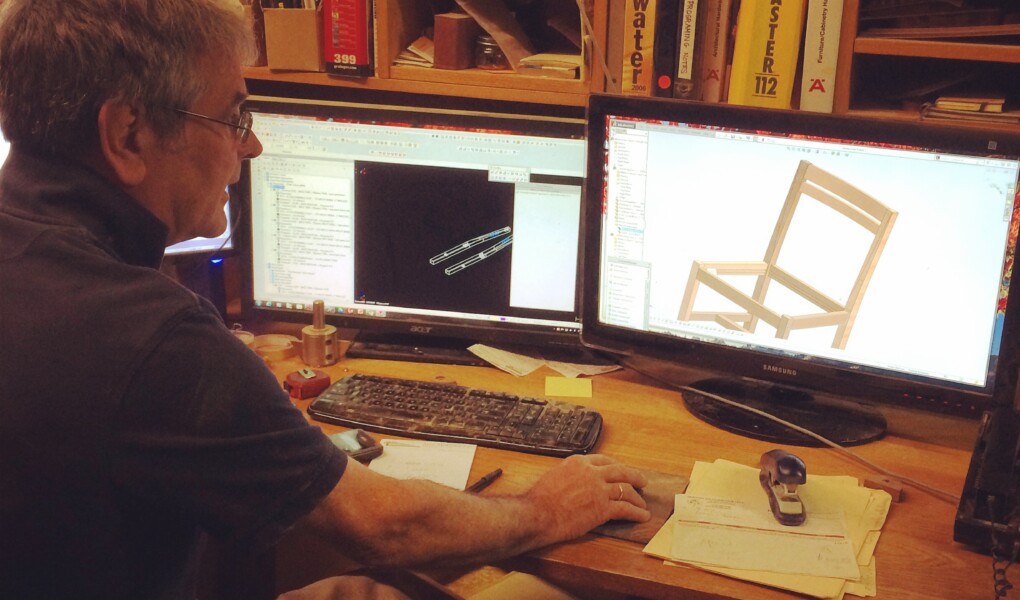

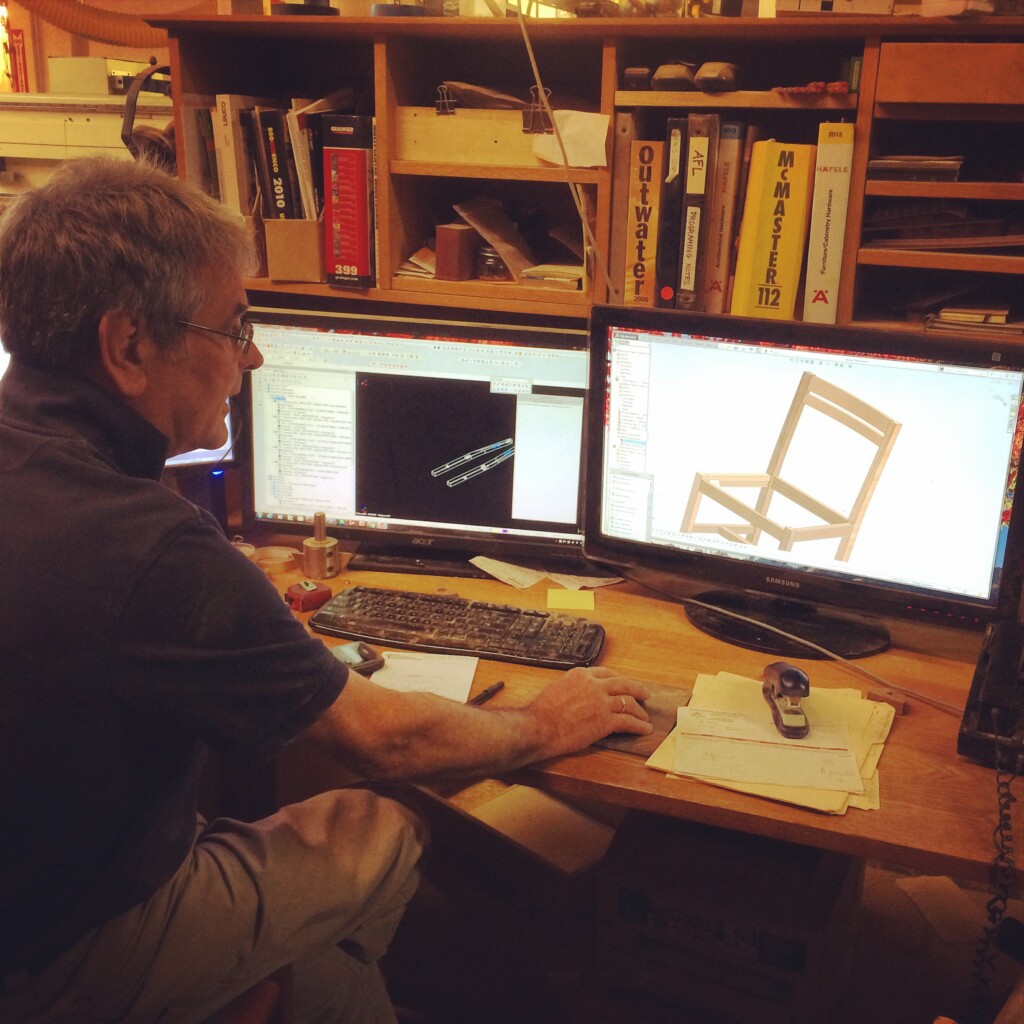

Today, Scott creates his designs not with pencil and paper (though every woodworker always has a pencil handy), but on Solidworks, a computer-aided design (CAD) program. These 3-D designs can be sent directly to the CNC machine, which can then cut out all the components for an entire piece of furniture as a single job. One of their dining chairs, for example, can be cut on this machine in about 20 minutes.

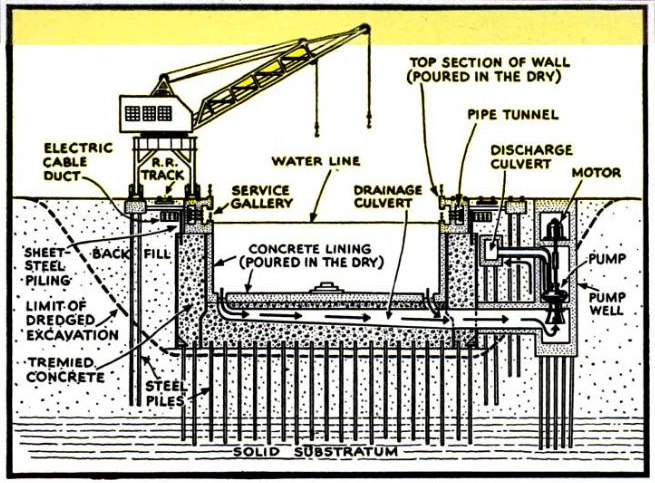

Here it is going to work:

But it’s not just the speed that is a game-changer. In traditional woodworking, pieces of furniture would be made in batches of 10 to 15, to maximize efficiency by making many identical components at once – classic interchangeable part production. That means you need a lot of raw materials on hand to make these larger batches. And while you may have an order placed for some of those chairs, there is no guarantee that you will sell the remaining ones you now have in stock, meaning you have a lot of capital and warehouse space tied up in lumber and unsold inventory.

With a CNC machine, there is almost no change in the efficiency if you make one chair or 10 chairs, as the machine can cut out all the components for a complete chair at once. This means that manufacturing can be done on demand, so there’s no guessing and hoping about what might sell in the future. Customization can also be done at minimal added cost – just a few clicks of the mouse in Solidworks – which has opened up many new opportunities for the business, including doing more custom cabinetry and offering a wider array of items. If a design doesn’t sell, it just sits on a hard drive, not in a warehouse.

In this case, automation facilitates not uniform mass production, but custom, small-batch production.

But Scott Jordan is about a lot more than efficient production and quality design. He cares deeply about the impact of his product on the environment and on people, both his customers and employees. Once the CNC machine does its work, a team of skilled craftsmen finishes and assembles the pieces by hand. All of their furniture is coated with a linseed oil-based finish, not chemical stains or paints, many of which contain harmful Volatile Organic Compounds (VOCs) and coal tar-based dyes. Because of the quality of the solid wood that they use in their furniture (mostly cherry, walnut, red oak, and poplar), the simple oil finish brings out the beautiful grain of the wood, and its safe to work with and breathe in. Similarly, Scott Jordan is also on a mission to make sure that whoever sleeps on their beds sleeps on a healthful, quality mattress. They sell only mattresses free of harmful chemicals (like the flame retardant PBDEs).

What is most remarkable about Scott is the passion and care he brings to his work after 35 years in business. He is not only a craftsman, but a great storyteller who loves sharing his work and insights. Be sure to join us for our next Making It In NYC: Inside Industry Tour on Friday, March 27 at 9:30am, and you can check out Scott’s furniture at their showroom at 137 Varick St in SoHo.