The Brooklyn Navy Yard has a long tradition of exploration. For 165 years, the Yard built, outfitted, and repaired ships that traveled millions of miles around the world, including building the first US Navy ship to circumnavigate the globe (USS Vincennes, 1826-30), dispatching the groundbreaking US Exploring Expedition (1838-42), and receiving the Navy’s first nuclear submarine USS Nautilus after it passed underneath the ice of the North Pole (1958). But none of these ships went as far or as deep into uncharted territory as systems developed by Brooklyn Navy Yard tenant Honeybee Robotics.

Founded in 1983 on Elizabeth St in Manhattan’s Lower East Side by current company Chairman Steve Gorevan and CFO Chris Chapman, Honeybee started life helping other companies integrate off-the-shelf robotic systems into their operations, working with clients like IBM, 3M, and ConEdison. Over the last 32 years, the company has greatly expanded its portfolio, and its offices, beyond their former home in a Manhattan piano factory, with facilities in Pasadena, CA, Boulder, CO, and since November 2014, in Building 3 at the Brooklyn Navy Yard.

We recently took a tour of Honeybee’s Navy Yard space with Honeybee’s Business Development Director John Abrashkin, in preparation for our Making It In NYC: Interstellar Industry Tour (which also features space suit maker Final Frontier Design). He told us that one of Honeybee’s strengths is developing robotic systems that can operate in extreme environments, places where humans cannot go or where the dangers would be excessive. Their robots have found applications in areas including mining, oil and gas exploration, infrastructure inspection, bomb disposal, and medical devices, and perhaps the most extreme environment of all: outer space.

In 1986, Honeybee received their first contract from NASA, and they have since worked on more than 300 space-related projects for the agency. Today, their systems can be found approximately 240 million miles away (at the current moment), on four different craft on the surface of Mars.

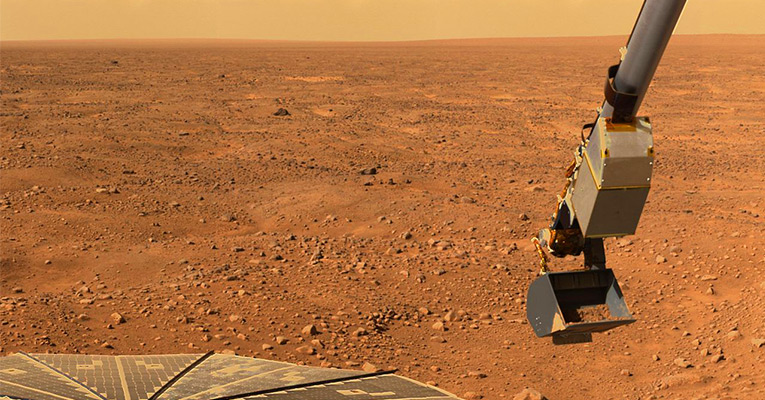

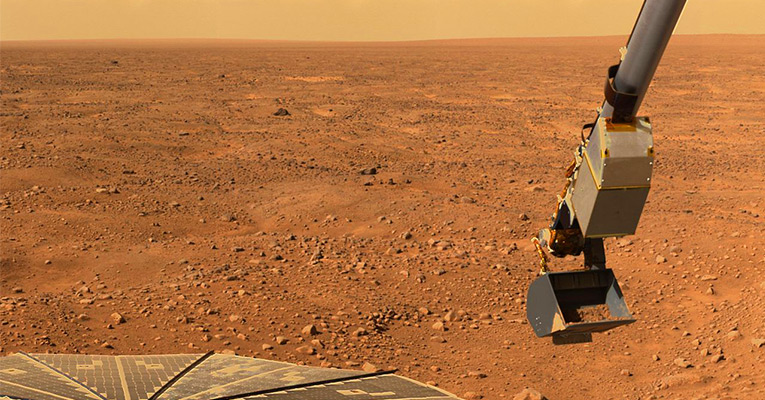

Their first foray into martian exploration was building the Rock Abrasion Tool (RAT) for the Opporuntiy and Spirit rovers, allowing them to collect samples from inside surface rocks. The craft reached Mars in 2004, and while Spirit hit some rough terrain in 2009 and has not moved since, Opportunity is still going strong, just recently completing a Martian Marathon, covering 26.2 miles in 11 years of operation. Then for NASA’s Phoenix lander in 2008, Honeybee was tasked with building the Icy Soil Acquisition Device (ISAD), which used a scoop on the end of a robotic arm to collect samples from the planet’s polar ice cap, yielding invaluable information about the martian climate and water cycle.

But Honeybee’s biggest Mars project has been aboard the ambitious Curiosity rover. The one-ton spacecraft is officially known as the Mars Science Laboratory, and that’s exactly what it is – a well-equipped lab on wheels that can collect and analyze a wider range of samples from the martian environment than any previous mission. And much of that experimentation would be impossible without Honeybee’s main contribution, the Sample Manipulation System (SMS). NASA describes it as “an under-actuated three-Degree-Of-Freedom (DOF) robotic system,” but in plain English, it is essentially a science lab “Lazy Susan.” With an array of 74 sample cups, the SMS can rotate to collect, organize, and preserve samples, and then deliver them to the appropriate analysis tool in the rover’s scientific payload. You can see how the system works below:

In addition to the SMS, Curiosity also carries Honeybee’s Dust Removal Tool (DRT), which builds on the company’s experience with surface sample collection and micro-excavation (watch it in action).

Still in space, but slightly closer to earth, Honeybee is also working on a project from the Defense Advanced Research Projects Agency (DARPA) known as Phoenix (not to be confused with the Mars mission). There are currently hundreds of satellites orbiting the earth, almost all of which have or will come to the end their useful lives; Phoenix aims to develop robotic plug-and-play modules that can easily repurpose those satellites and reduce the need for new and expensive satellite launches. DARPA’s concept video shows how it works:

Much of this work is supported by NASA’s Small Business Innovation Research program, which targets a certain percentage of project funding towards US-based small businesses. Not only does this program tap into diverse range of innovators – not just aerospace giants and major research institutions – it also supports domestic manufacturing and expertise, and helps these companies find commercial applications for their technologies. In NASA’s report on the contributions of small businesses to the Curiosity mission, Honeybee was one of just seven companies highlighted for their exceptional work, from among hundreds of contractors and subcontractors on the project.

Today, Honeybee divides its efforts between commercial clients and work for the federal government. While most of the space-related work happens at Honeybee’s Pasadena office – located close to the venerable Jet Propulsion Laboratory – their Brooklyn office is staffed by what Abrashkin calls “omnivorous roboticists,” working on a range of commercial projects. These include a gas pipeline inspection robot and medical devices for robotic surgery, giving a human surgeon more precision control and being even less invasive than current laparoscopic techniques.

Abrashkin pointed out that there is a lot of overlap between space systems and medical devices. In medical and space applications, you are often working within constraints on the size of and power available to the system, and everything is treated as “mission critical” – the system must work every time and have built-in redundancies.

For Honeybee, a major advantage to being inside the Brooklyn Navy Yard is access to other companies that are working in similar fields or can supply components. Their Building 3 space is just temporary, as they will eventually move into the Green Manufacturing Center as part of New Lab, a digital design and fabrication space that provides companies with shared equipment and opportunities for collaboration. With a diverse range of projects on their plate that often require customized solutions, Honeybee is looking to take advantage of New Lab’s assets and expertise in 3-D printing to help meet their “omnivorous” needs.

Turnstile Tours offers the Making It In NYC: Inside Industry Tour of the Brooklyn Navy Yard monthly, as well as other themed tours of the Yard every weekend throughout the year. All tours are offered in partnership with and begin at the Brooklyn Navy Yard Center at BLDG 92, which offers free admission to three floors of exhibitions on the Yard’s history, and a host of great special events and programs.